Products

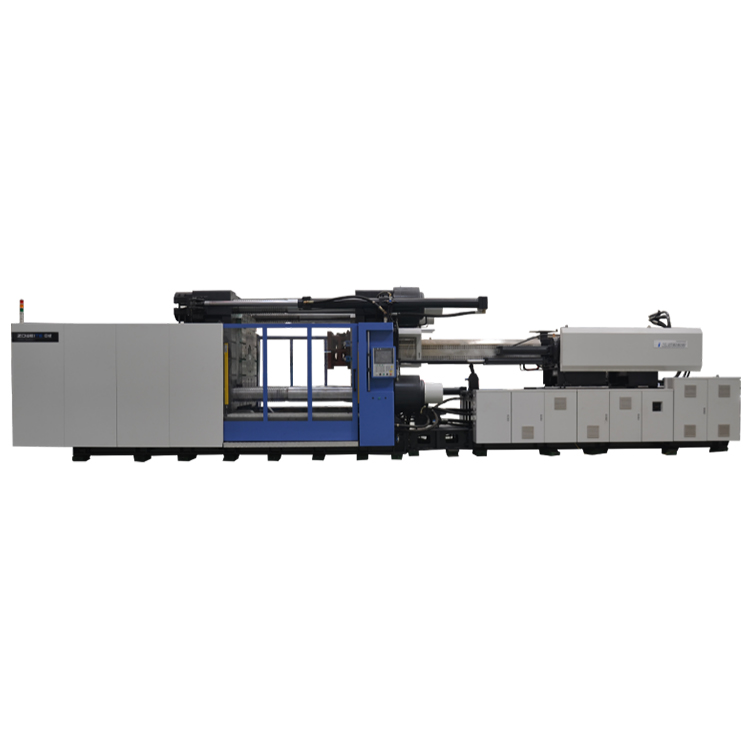

Servo Energy Saving Plastic Injection Molding Machine

Energy conservation and environmental protection are the mainstream of modern industrial development. ZOWEITE® injection molding machine company focuses on the new servo energy saving technology of injection molding machine. The servo energy saving injection molding machine has realized the excellent characteristics of high energy, high precision, high response, low noise, low oil temperature. It can be widely used in the injection molding of plastic carts such as auto parts, industrial dustbin, plastic crate and larger plastic pallet.

Send Inquiry

Product Description

Energy conservation and environmental protection are the mainstream of modern industrial development. ZOWEITE injection molding machine company focuses on the new servo energy saving technology of injection molding machine. The Servo Energy Saving Plastic Injection Molding Machine has realized the excellent characteristics of high energy, high precision, high response, low noise, low oil temperature. It can be widely used in the injection molding of plastic carts such as auto parts, industrial dustbin, plastic crate and larger plastic pallet.

What are the advantage of Servo Energy Saving Plastic Injection Molding Machine?

1.Agile and efficient.

The ordinary injection molding machine is inefficient and does not meet the requirements and standards of modern industrial development. ZOWEITE® Servo Energy Saving Plastic Injection Molding Machine adopts a new servo technology, adopts optimized motor design and advanced computing devices to realize the magnetic filed oriented vector control strategy. Compared with the ordinary injection molding machine. ZOWEITE® Servo Energy Saving Plastic Injection Molding Machine is correspondingly faster( the fast start time is only 0.5s, and the maximum speed of servo motor is 2500 RPM (from zero speed to the maximum speed is only 36 milliseconds), with short cycle time and high efficiency. The injection molding machine with new servo technology can significantly speed up the advance and retreat of ejector pin and further improve the efficiency.

2.Stable precision

The servo motor system used by ZOWEITE® is a closed-loop system. The injection molding machine can provide as much pressure flow as it needs, no more or less, and the production products are very stable. At the same time, the high-precision resolver is used as the motor speed feedback component and the high-precision pressure sensor is used as the pressure feedback component, and the double closed-loop control of pressure and flow is carried out. Various control algorithms are realized by using high-speed DSP. The average pressure error can reach 0.5bar, the speed control error is 0.1%, and the hysteresis is zero, which effectively ensures the high-precision repeatability of products.

3.Low energy consumption and environmental protection

Servo Energy Saving Plastic Injection Molding Machine advocates the standard of energy saving. The injection molding machine of ZOWEITE servo technology and the traditional injection molding machine have higher efficiency under the same working state, More environmentally friendly (achieve 20% - 80% energy-saving rate). Moreover, the new energy-saving technology can avoid the rise of oil temperature, the reduction of water cooling capacity and the reduction of temperature rise, so it can better save hydraulic oil and effectively reduce cost and increase efficiency for the majority of injection molding enterprises.

ZOWEITE injection molding machine can provide Turn-key project for customers, including injection molding machine, mold, auxiliary equipment and plant design, etc. ZOWEITE injection molding machine will recommend the suitable machine according customers’ requirements and budget. Welcome to contact us.