Servo Injection Molding Machine for Plastic Basket Bucket Crate Manufacturers

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Servo Injection Molding Machine for Plastic Basket Bucket Crate,High Quality Injection Molding Machine for Plastic Crate,Hot Sell Plastic Crate Injection Molding Machine,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine,Plastic Transportation Crate Injection Mould Molding, We are now looking forward to even greater cooperation with overseas customers based on mutual benefits. If you are interested in any of our products, please feel free to contact us for more details.

Servo Injection Molding Machine for Plastic Basket Bucket Crate, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

Hot Products

200 Ton Injection Molding Machine

ZOWEITE® 200 Ton Injection Molding Machine is a standard machine, mainly used to produce various strips, tape, bottle cap, hanger, pipe fittings and other plastic products.The 200ton injection molding machine is a small injection molding machine, which covers a relatively small area, saves area cost, and has relatively convenient transportation, without disassembly.Food Container Injection Molding Machine

ZOWEITE® Food Container Injection Molding Machine is thin-walled food packaging, which requires extremely high injection speed. Ordinary injection molding machine can not meet the requirements of thin-walled food container, because the injection molding pressure of ordinary injection molding machine is small and slow speed.It works similar to a syringe for injection by using the thrust of the screw into the closed mold cavity and curing the product. Our offered machine is developed with supreme grade raw materials and latest technology in compliance with set industry standards and to ensure its high quality and durability. Moreover, it is extensively used in various molding applications.Vegetable And Fruit Injection Molding Machine

ZOWEITE® Vegetable And Fruit Injection Molding Machine made in China is a special machine for producing fruit and vegetable baskets. It is a special model for disposable plastic fruit basket production equipment developed by our company according to the characteristics of fruit and vegetable baskets. The vegetable and fruit basket injection molding machine has the latest domestic technology, novel structure, high speed, high efficiency, low dryness and energy saving.400 Ton Molding Machine

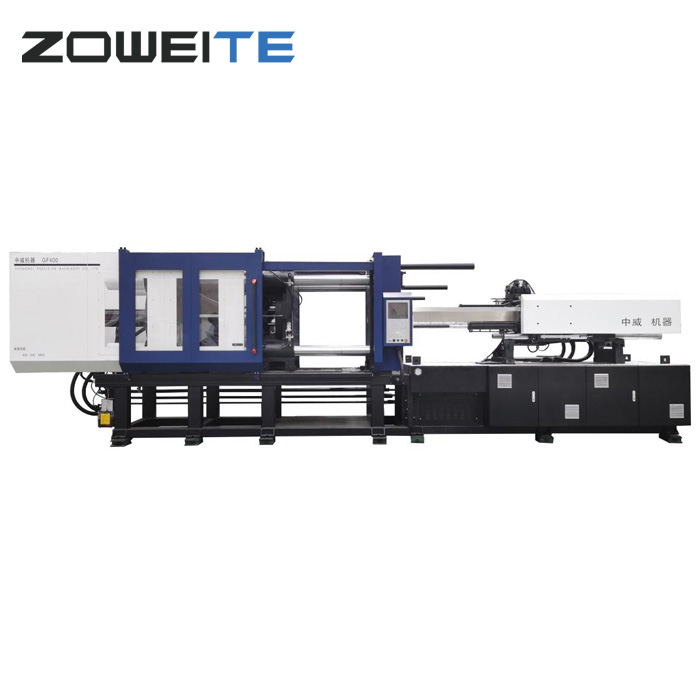

ZOWEITE® has 30 years of experience in this industry and obtained ISO 9001 and SGS certification. ZOWEITE® has many high-quality machines, i will focus on the 400 ton molding machine.If you are interested in our products, then please contact us, we will give you the most suitable quotation.Auto bumper injection molding machine

ZOWEITE® Auto bumper injection molding machine is an injection molding machine specially used to produce auto bumpers. According to the volume and weight of auto bumpers, ZOWEITE Injection Molding Machine has launched two injection molding machines for producing automobile bumpers - 1500 ton and 2300 ton injection molding machines. The auto bumper injection molding machine is easy to maintain, and the warranty period is one year, if you are interested, please contact us.Logistic Crate Injection Molding Machine

ZOWEITE® has rich experience for producing injection molding machines more than 30 years, we keep on innovating and updating our technology.Today I would like to share our Logistic crate injection molding machine and mold information with you.