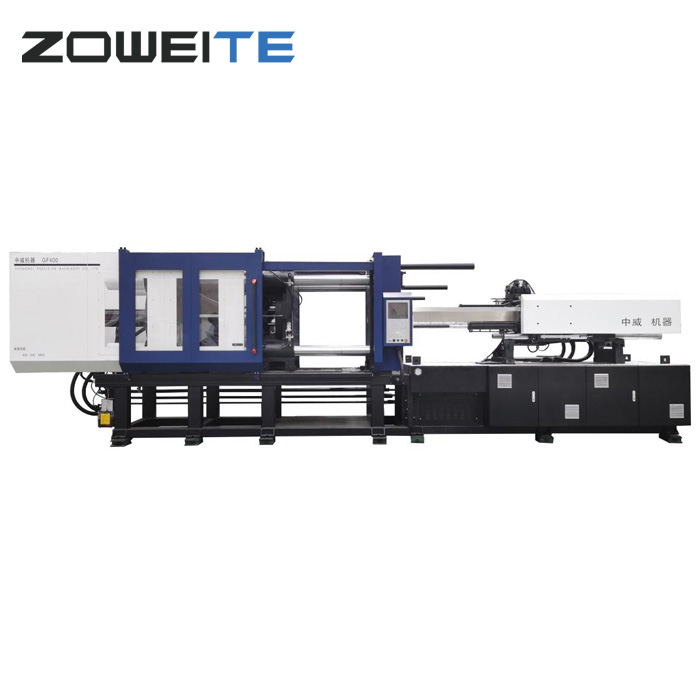

Servo Injection Molding Machine for Plastic Basket Bucket Crate Manufacturers

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Servo Injection Molding Machine for Plastic Basket Bucket Crate,High Quality Injection Molding Machine for Plastic Crate,Hot Sell Plastic Crate Injection Molding Machine,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine,Plastic Transportation Crate Injection Mould Molding, We are now looking forward to even greater cooperation with overseas customers based on mutual benefits. If you are interested in any of our products, please feel free to contact us for more details.

Servo Injection Molding Machine for Plastic Basket Bucket Crate, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

Hot Products

Plastic Molding Machine

ZOWEITE® Plastic molding machine made in China is a kind of machine for plastic product. The molten plastic is injected into the plastic product mold by pressure, cooled and molded to obtain all kinds of plastic parts. There is a special mechanical plastic molding machine for injection molding. At present, the most commonly used plastics are polyethylene, ABS, PA, etc.Bottle Cap Injection Molding Machine

With the increase in the use of plastic bottles, the frequency of use of plastic bottle caps has increased simultaneously. If you want to achieve high-yield plastic caps, you must use high-yield bottle cap injection molding machines. ZOWEITE® injection molding machine from China has bottle cap injection molding machines-GF200 and GF260.Injection Moulding Machine For Bottle Caps

ZOWEITE® injection moulding machine for bottle caps is used to produce all kinds of bottle caps of mineral water bottles and beverage bottles. Different molds and machines are determined according to different bottle cap sizes. Plastic bottle caps are also divided into different production processes. Only the injection molding production process needs the injection molding machine to produce.200 Ton Injection Molding Machine

ZOWEITE® 200 Ton Injection Molding Machine is a standard machine, mainly used to produce various strips, tape, bottle cap, hanger, pipe fittings and other plastic products.The 200ton injection molding machine is a small injection molding machine, which covers a relatively small area, saves area cost, and has relatively convenient transportation, without disassembly.Pet Bottle Preform Machine

ZOWEITE® PET Bottle Preform Machine made in China is an optimized injection molding machine for PET injection molding. It is the important PET equipment in the manufacturing process of PET bottle blank. Even in the whole PET Bottle Preform Machine are specially designed according to the characteristics of PET materials.Plastic Pallet Injection Molding Machine

Plastic pallet injection molding machine are widely used in the logistics chain to realize the transportation, loading, unloading, distribution,storage and other links of upstream and downstream enterprises are consistent integrated operation, so that enterprises can carry out efficient logistics and transportation. ZOWEITE® injection molding machine research and development team according to the needs of the market and customer development and optimize a wide variety of plastic tray series, including grid nice foot series, flat nine foot series, grid Sichuan character series, grid field word series, grid two side series, flat field word series , flat Sichuan character series, at the same time can provide customers with high quality plastic tray molding solutions.