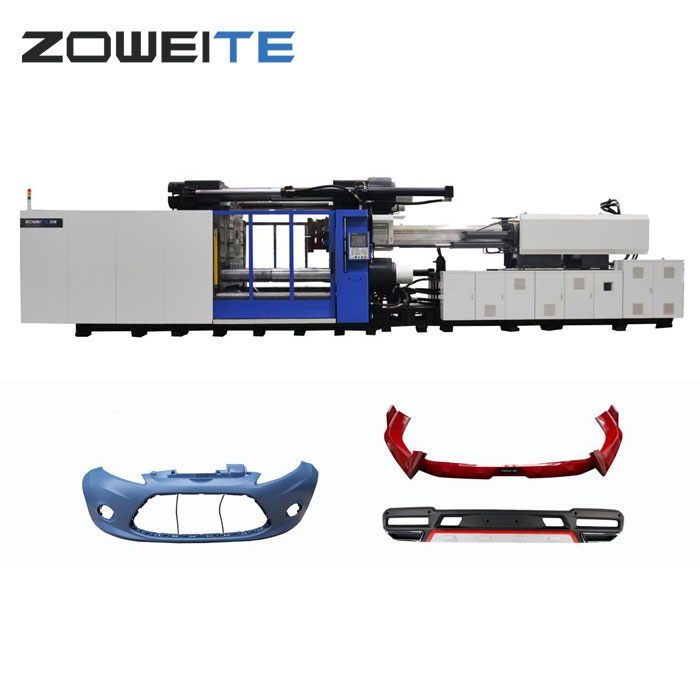

Tray Injection Molding Machine

The Tray injection molding machine is one of the two platen machines. The Tray injection molding machine is specially used to produce plastic pallets used in the industry. ZOWEITE® provide Turn-key project for our customers, including plant design, whole injection molding machines production lines sourcing, machines installation, testing and commissioning.

Send Inquiry

The ZOWEITE® tray injection molding machine is one of the two platen machines. The tray injection molding machine is specially used to produce plastic pallets used in the industry.

The advantages of tray injection molding machine are as follow :

1.The body is short and occupies a small area;

2.Large mold opening stroke, suitable for deepcavity molds;

3.Better mode locking balance;

4.Compared with the three platen injection molding machine of the same tonnage, it saves energy;

5.The use cost is low, the five machine twist structure is free of lubrication, saves a lot of lubricating oil, and the maintenance is simple;

6.No need to adjust the mold, easy to operate.

The role of the mold temperature machine in the tray injection molding machine:

The role of the mold temperature machine in the ZOWEITE® tray injection molding machine is used to adjust the equilibrium mold temperature of the mold, which can be heated or cooled. The mold temperature machine utilizes a thermally conductive medium with high thermal conductivity in order to send away the excess heat in the mold in a very short time. After the thermal equilibrium temperature is set, the temperature can be automatically controlled within a very small error, and the constant value can be maintained. After the thermal equilibrium temperature is set, the temperature can be automatically controlled within a very small error, and the constant value can be maintained.

The function of the mold temperature machine is to heat the mold and maintain its working temperature to ensure stable quality of injection molded parts and optimize processing time. In the injection molding machine industry, the temperature of the mold has a decisive effect on the quality and injection time of the injection molded parts.

The heat balance of the injection mold controls the heat conduction of the injection molding machine and the mold is the key to the production of injection molded parts. Inside the mold, the heat brought by the plastic (such as thermoplastic) is transferred to the material and the steel of the mold by thermal radiation , and to the heat transfer fluid by convection. In addition, heat is transferred to the atmosphere and formwork by thermal radiation. The heat absorbed by the heat transfer fluid is taken away by the mold temperature machine. The thermal balance of the mold can be described as:P=Pm-Ps. In the formula, P is the heat taken away by the mold temperature machine; Pm is the heat introduced by the plastic; Ps is the heat emitted by the mold to the atmosphere.

The purpose of controlling the mold temperature of the tray injection molding machine and the influence of the mold temperature on the injection molded parts in the injection molding process, the main purpose of controlling the mold temperature is to heat the mold to the working temperature, and the second is to keep the mold temperature constant at the working temperature. If the above two points are successful, the cycle time can be optimized, thereby ensuring the stable and high quality of the injection molded parts. Mold temperature affects surface quality, fluidity, shrinkage, injection cycle time, and deformation. Excessive or insufficient mold temperature will have different effects on different materials. For thermoplastics, a higher mold temperature generally changes surface quality and flow, but increases cooling time and injection cycle time. Lower mold temperature will reduce shrinkage in the mold, but will increase the shrinkage of the injection molded part after demolding. For thermosets, a higher mold temperature generally reduces cycle time, which is determined by how long it takes for the part to cool. In addition, in the processing of plastic , a higher mold temperature will also reduce the plasticizing time and reduce the number of cycles.

Preliminary conditions for effectively controlling the mold temperature of the tray injection molding machine. The temperature control system consists of three parts: mold, mold temperature machine, and heat transfer fluid. In order to ensure that heat can be applied to or removed from the mold, the various parts of the system must meet the following conditions: first, inside the mold, the surface area of the cooling channel is large enough, and the diameter of the runner must match the capacity of the pump( pump pressure). The temperature distribution in the cavity has a great influence on part deformation and internal pressure, thereby improving the quality of injection molded parts. He can also shorten cycle times and reduce product costs. Secondly, the mold temperature machine must be able to keep the temperature of the heat transfer fluid constant within the range of 1℃-3℃, which is determined according to the quality requirements of the injection molded parts. The third is that the heat transfer fluid must have good thermal conductivity, and most importantly, it must bo able to import or export a large amount pf heat in a short time. From a thermodynamic point of view, water is significantly better than oil.