high speed injection molding machines Manufacturers

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for high speed injection molding machines,Thin wall products injection molding machine,injection molding machine,high speed injection molding machine, The concept of our company is "Sincerity, Speed, Service, and Satisfaction". We'll follow this concept and win far more and much more customers' pleasure.

high speed injection molding machines, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

Hot Products

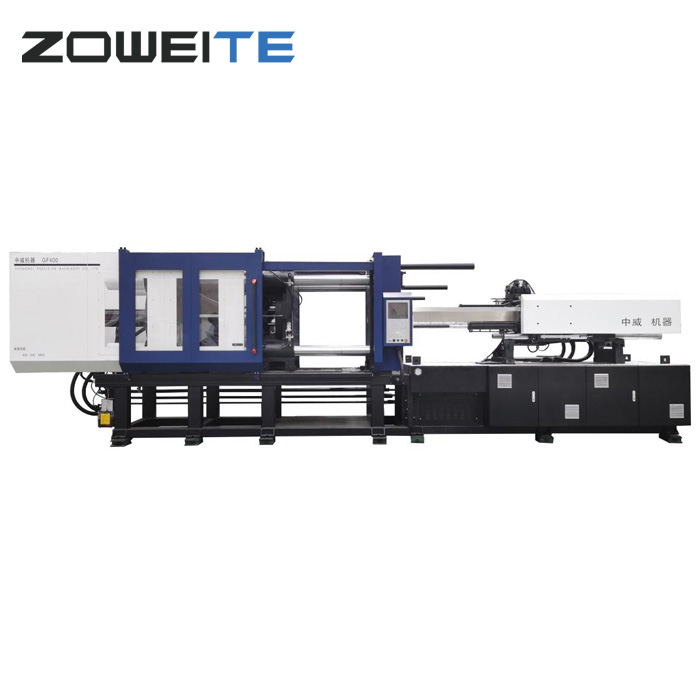

Plastic Injection Molding Equipment

ZOWEITE® Plastic injection molding equipment made in China, also known as plastic injection molding machine, is a device that makes various types of plastic raw materials into desired products or preforms.PET Bottle Preform Injection Molding Machine

PET bottle preform are processed again by blow molding to form plastic bottles, including bottles used for packaging cosmetics, medicine, health care, beverages, mineral water, reagents, etc. this bottle making method is called two-step method, that is, the method of forming bottle blanks by ZOWEITE® PET bottle preform injection molding machine and PET plastic bottles by blow molding again.Milk Tea Cup Injection Molding Machine

ZOWEITE® Milk tea cup injection molding machine from China is also a kind of thin-wall packaging injection molding, which also has high requirements for injection pressure and machine. ZOWEITE® KC series injection molding machine which is a special machine for produce milk tea cup.400 Ton Molding Machine

ZOWEITE® has 30 years of experience in this industry and obtained ISO 9001 and SGS certification. ZOWEITE® has many high-quality machines, i will focus on the 400 ton molding machine.If you are interested in our products, then please contact us, we will give you the most suitable quotation.Nylon Cable Tie Injection Molding Machine

ZOWEITE® Nylon cable tie injection molding machine made in China, the machine is easy to maintain and has a one-year warranty. ZOWEITE has been in injection molding machine for 30 years. We provide Turn-Key project, include plant design, whole production line and mold, machines installation and workers training. Nylon cable ties injection moulding machine is a machine specially used to produce plastic nylon cable ties. It can produce various nylon cable ties according to different needs of customers.Two Platen Packaging Injection Molding Machine

A Two Platen Packaging Injection Molding Machine is a type of injection molding machine used in the production of plastic packaging materials. Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity, which then cools and solidifies to form the desired product.