PET preform injection molding machine Manufacturers

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for PET preform injection molding machine,Pesticide bottle PET preform injection molding machine,preform injection molding machine,PET injection molding machine,injection molding machine, We warmly welcome all intrigued customers to speak to us for additional information and facts.

PET preform injection molding machine, We have been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to provide you happy solutions.

Hot Products

PET Bottle Preform Injection Molding Machine

PET bottle preform are processed again by blow molding to form plastic bottles, including bottles used for packaging cosmetics, medicine, health care, beverages, mineral water, reagents, etc. this bottle making method is called two-step method, that is, the method of forming bottle blanks by ZOWEITE® PET bottle preform injection molding machine and PET plastic bottles by blow molding again.400 Ton Injection Molding Machine

The ZOWEITE® 400 ton injection molding machine has a clamping force of 4000KN, and the 400 ton large screw machine is about 1000 grams, and the maximum can reach 700~800 grams. The products are different, and the results are different.Garbage Can Injection Molding Machine

ZOWEITE® Garbage can injection molding machine made in China is a plastic garbage can injection molding production process, which is: raw material mixing - mixed raw material addition - commissioning process, melting to liquid through high-temperature screw - injecting into mold cavity - cooling molding - opening mold to take out products, and then complete the production of plastic garbage can.PVC tube injection molding machine

ZOWEITE® PVC tube injection molding machine is standard machine and it is suitable for produce various tubes. As a professional manufacturer and supplier of PVC tube injection molding machines, ZOWEITE PVC tube injection molding machine has always provided high-quality injection molding equipment for manufacturers in the building materials industry at home and abroad to help customers develop, Highly praised by customers.Auto bumper injection molding machine

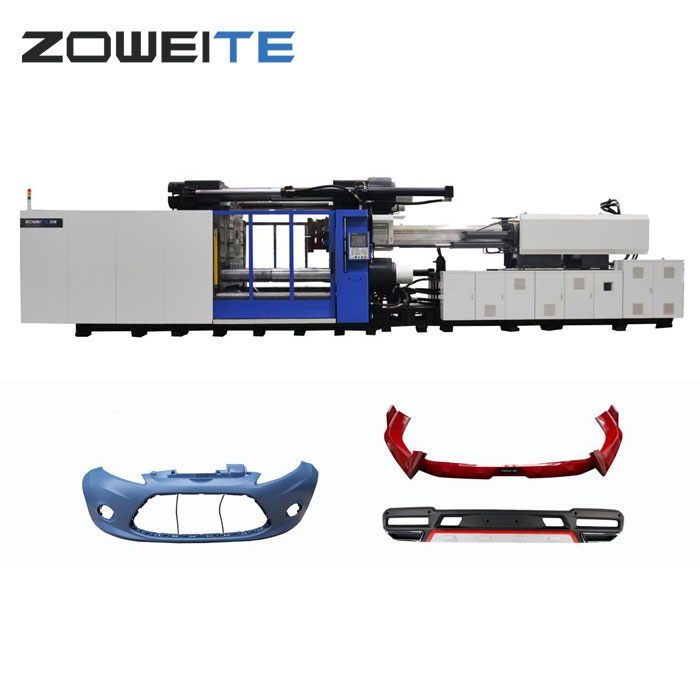

ZOWEITE® Auto bumper injection molding machine is an injection molding machine specially used to produce auto bumpers. According to the volume and weight of auto bumpers, ZOWEITE Injection Molding Machine has launched two injection molding machines for producing automobile bumpers - 1500 ton and 2300 ton injection molding machines. The auto bumper injection molding machine is easy to maintain, and the warranty period is one year, if you are interested, please contact us.Plastic Bucket Injection Molding Machines

ZOWEITE® is manufacturer and supplier for providing customers with bucket injection turnkey engineering. If you are planning to invest in new projects of Plastic Bucket Injection Molding Machines and injection mold. Then please contact us.