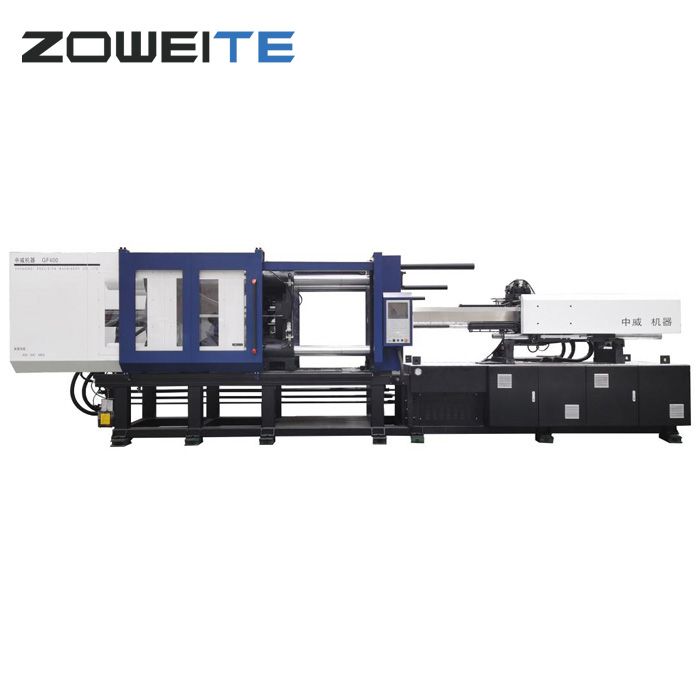

Two Platen Injection Molding Machine Manufacturers

The key to our success is "Good Products Good quality, Reasonable Price and Efficient Service" for Two Platen Injection Molding Machine,Two Platen Packaging Injection Molding Machine,Two Platen Molding Machine,Injection Molding Machine, In order to expand our international market, we mainly supply our oversea customers Top quality performance products and service.

Two Platen Injection Molding Machine, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we present, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and comprehensive parameters and any other info weil be sent for you timely for your inquiries. So make sure you make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We have been confident that we are intending to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

Hot Products

Injection Moulding Machine For Bottle Caps

ZOWEITE® injection moulding machine for bottle caps is used to produce all kinds of bottle caps of mineral water bottles and beverage bottles. Different molds and machines are determined according to different bottle cap sizes. Plastic bottle caps are also divided into different production processes. Only the injection molding production process needs the injection molding machine to produce.Pet Preform Machine

ZOWEITE® PET preform machine made in China series is specially designed and manufactured according to PET material molding technology, such as special design of screw and cylinder, precision controller for cylinder heating, pull rod space, nozzle, injection system,amplification motor and oil pump. Our PET preform machine is widely used in different PET molding products, including PET water preforms, soft drink bottle preforms, edible oil bottle preforms, 3 gallon and 5 gallon PET preform, etc.Pet Preform Injection Machine

ZOWEITE® PET preform injection machine is specially designed and manufactured according to PET material molding technology. Such as screw and barrel body design, cylinder heating precision controller, etc. ZOWEITE® have 30 years experience in injection molding machine industry. We have launched special injection molding machine for PET preform: 260 ton, 320 ton, 400 ton, etc .Plastic Vegetable Basket Injection Molding Machine

Plastic vegetable basket injection molding machine is an special designed injection molding machine for plastic vegetable basket. It is suitable for the injection molding machine of fruit basket, vegetable basket and other disposable waste turnover baskets. ZOWEITE® GF400K, GF530K and other injection molding machine are specially developed by ZOWEITE® for fruit and vegetable basket.Nucleic acid detection reagent tube injection molding machine

ZOWEITE® Nucleic acid detection reagent tube injection molding machine is a machine for producing nucleic acid detection reagent tubes. Generally, it uses an ordinary machine of 200ton or larger, which depends on the output of customers and is determined according to the size and output of customers.ZOWEITE factory is a manufacturer of nucleic acid detection reagent tube machines, which can provide high-quality machines.Two Platen Packaging Injection Molding Machine

A Two Platen Packaging Injection Molding Machine is a type of injection molding machine used in the production of plastic packaging materials. Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity, which then cools and solidifies to form the desired product.