Two Platen Packaging Injection Molding Machine Manufacturers

keep on to improve, to make sure solution good quality in line with market and shopper standard requirements. Our business has a top quality assurance program are actually established for Two Platen Packaging Injection Molding Machine,Two Platen Injection Molding Machine,Two Platen Molding Machine,Injection Molding Machine, We welcome new and aged consumers to speak to us by telephone or send out us inquiries by mail for long term company associations and attaining mutual results.

Two Platen Packaging Injection Molding Machine, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. Now we have tightened inspection for quality of product.

Hot Products

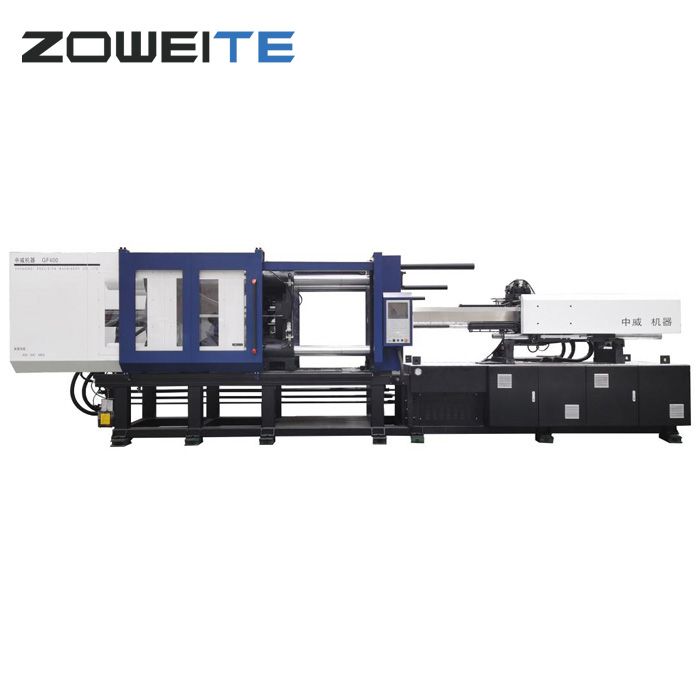

650 Ton Injection Molding Machine

ZOWEITE® Injection molding machine is a kind of main molding equipment that uses thermoplatic or thermosetting materials to make plastic products of various shapes with plastic molding molds. The injection molding machine is usually composed of injection system, clamping system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc. ZOWEITE 650 ton injection molding machine is a special injection molding machine for plastic bucket, which is suitable for injection molding machine of barrel products for lubricating oil bucket, paint bucket, chemical fertilizer bucket, and other purposes. ZOWEITE 650 ton injection molding machine also has standard machines. We can recommend the suitable machines according customers’ requirements.Vegetable and Fruit Basket Making Machine

ZOWEITE® vegetable and fruit basket making machine has a short cycle cycle, high production efficiency, abrasion-resistant screw barrel and screw, and has a very high cost performance. It is a special model specially developed for turnover baskets, plastic baskets, fruit baskets, and seafood basket storage boxes.High Speed Plastic Making Machine

ZOWEITE® High speed plastic making machine can also be calling high speed injection molding machine or high speed injection machine. Tianjin Yihe Zhongwei (ZOWEITE) Precision Machinery Co., Ltd is a high-tech enterprise specialized in designing, manufacturing and selling various types of high-precision, energy saving, stable performance injection molding machines in China.2300ton Injection Molding Machine

The ZOWEITE® 2300ton injection molding machine is a relatively large injection molding machine in the injection molding machine industry. It can be specifically used to produce 120L and 240L trash cans,pallets,car bumpers,large chairs and other plastic products,the manufacturer will limit the size of the customer’s mold through a reasonable arrangement of code mold holes.Plastic bottle cap injection molding machine

ZOWEITE® Plastic bottle cap injection molding machine can produce mineral water bottle caps, automatic flip bottle caps, 5 gallon bottle caps, children’s anti-theft capsule caps, etc. ZOWEITE® machinery manufacture according to different sizes of bottle caps and customer requirements, we have developed 120 tons to 320 tons machine. We will provide the suitable machine , best price and completer bottle cap injection molding production line for customers according to their requirements.Pesticide Bottle PET Preform Injection Molding Machine

Good day and I would like to share our Pesticide bottle PET preform injection molding machine and mold information with you.