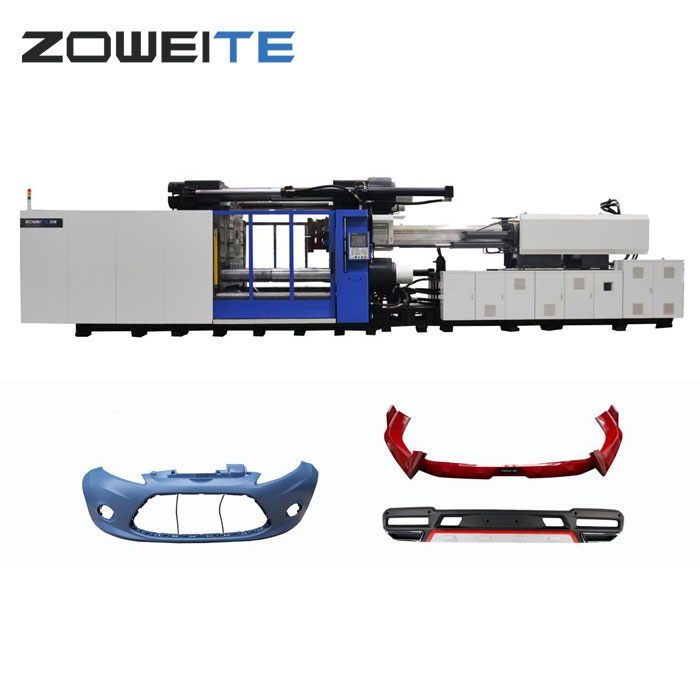

Easy maintenance 310 tons injection molding machine Manufacturers

we could supply high quality solutions, aggressive value and greatest customer support. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Easy maintenance 310 tons injection molding machine,High speed 310 tons injection molding machine,High Response Hybrid Servo System 310 tons injection molding machine,Rigid support structure310 tons injection molding machine,Food container310 tons injection molding machine, Constantly for the majority of business enterprise users and traders to supply ideal top quality products and great service. Warmly welcome to join us, let's innovation with each other, to flying dream.

Easy maintenance 310 tons injection molding machine, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Hot Products

Cable Tie Injection Molding Machine

Plastic tie is made of ZOWEITE® cable tie injection molding machine in China. In its manufacturing process, it is extruded through cable tie injection molding machinemold, and then the shape of the molded product presents a narrow strip. The main application fields of tie are very wide, including automobile industry, electronic industry, electrical industry, industrial field, manufacturing field and other industries. It plays the role of binding, tightening or arranging wires in places.Pvc Pipe Fitting Injection Molding Machine

ZOWEITE® PVC pipe fitting injection molding machine made in China is a machine for producing pipe fittings of various shapes,A pipe fitting is a part that connects a pipe into a pipe run.400 Ton Injection Molding Machine

The ZOWEITE® 400 ton injection molding machine has a clamping force of 4000KN, and the 400 ton large screw machine is about 1000 grams, and the maximum can reach 700~800 grams. The products are different, and the results are different.Chair Injection Molding Machine

ZOWEITE® Chair injection molding machine made in China is specially used to produce chair injection molding machine, like our life more ordinary plastic chairs are used with injection molding machine to produce.PET Bottle Preform Moulding Machine

ZOWEITE® Machinery company has developed a special PET bottle preform moulding machine according customers requirements.ZOWEITE GF260/GF320/GF400 injection molding machine is a special designed machine for PET preform.ZOWEITE Machinery manufacturer are in a good position not only to supply you high quality machinery, but also the excellent after sales service. Well-trained engineers will offer you any technical support.Thin wall products injection molding machine

A thin wall products injection molding machine is a specialized type of injection molding machine designed to produce thin-walled plastic products with high precision and efficiency.ZOWEITE® has 30 years experience in injection molding machine industry.