Flower pot320 tons injection molding machine Manufacturers

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Flower pot320 tons injection molding machine,High-speed 320 tons injection molding machine,High Response Hybrid Servo System 320 tons injection molding machine,Rigid support structure320 tons injection molding machine,Food container320 tons injection molding machine, We attend seriously to produce and behave with integrity, and with the favor of consumers at your house and abroad during the xxx industry.

Flower pot320 tons injection molding machine, Taking the core concept of "to be the Responsible". We will redound up on society for high quality solutions and good service. We are going to initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Hot Products

New Injection Molding Machine

ZOWEITE® injection molding machine only sells new injection molding machine, not old ones. We are a professional injection molding machine manufacturer. We have been in this industry for 30 years and have rich experience.Trash Can Special Injection Molding Machine

ZOWEITE® Trash Can Special Injection Molding Machine for trash cans is a machine specially used to produce environmentally protection, medical and household trash cans. Since the introduction of the garbage sorting policy in 2019, the national policy is bound to drive the economy. The nationwide promotion of garbage sorting has created a business opportunity for the plastic production industry-trash can manufacturing.Car Bumper Injection Molding Machine

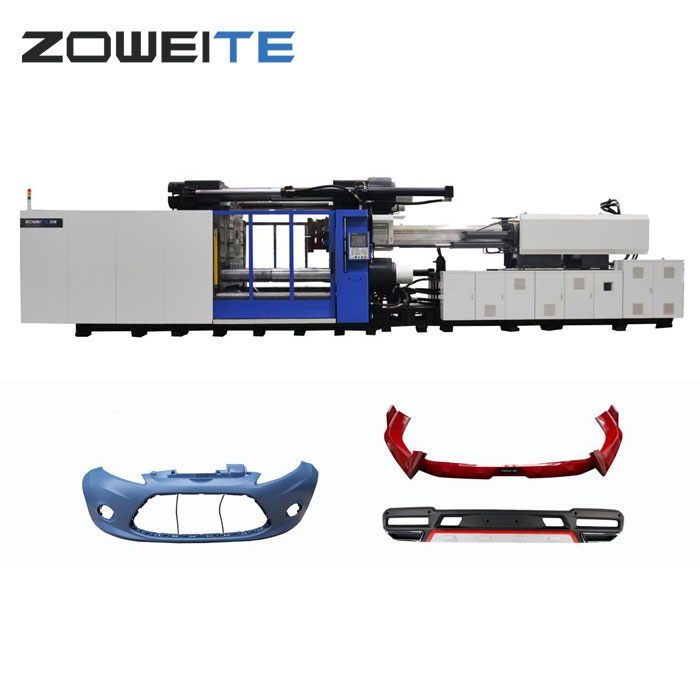

With the rapid development of automobile industry, plastic parts are more and more widely used in automobiles. The application of automobile plastic parts has significant effects on reducing automobile quality, saving fuel, promoting environmental protection and recyclability. Car Bumper Injection Molding Machine bumper mainly adopts injection molding. ZOWEITE® GF2300LB machine is specially designed for bumper.120 tons injection molding machine

ZOWEITE® 120 tons injection molding machine is a small injection molding machine with small floor area. It is suitable for producing all kinds of small plastic parts, such as plastic caps, nylon cable ties, etc. ZOWEITE® 120 tons injection molding machine has servo machine and standard injection molding machine. ZOWEITE manufacturer can also provide the suitable machine and best offer according client’s requirements.Nucleic acid detection reagent tube injection molding machine

ZOWEITE® Nucleic acid detection reagent tube injection molding machine is a machine for producing nucleic acid detection reagent tubes. Generally, it uses an ordinary machine of 200ton or larger, which depends on the output of customers and is determined according to the size and output of customers.ZOWEITE factory is a manufacturer of nucleic acid detection reagent tube machines, which can provide high-quality machines.Auto bumper injection molding machine

ZOWEITE® Auto bumper injection molding machine is an injection molding machine specially used to produce auto bumpers. According to the volume and weight of auto bumpers, ZOWEITE Injection Molding Machine has launched two injection molding machines for producing automobile bumpers - 1500 ton and 2300 ton injection molding machines. The auto bumper injection molding machine is easy to maintain, and the warranty period is one year, if you are interested, please contact us.