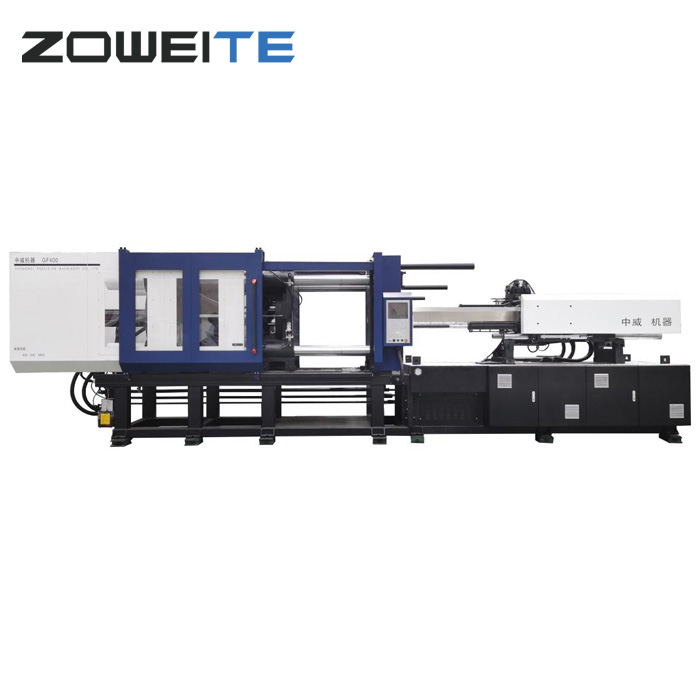

GF530ceh Servo System Injection Molding Machine for Plastic Crate Manufacturers

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for GF530ceh Servo System Injection Molding Machine for Plastic Crate,High Quality Injection Molding Machine for Plastic Crate,Servo Injection Molding Machine for Plastic Basket Bucket Crate,Hot Sell Plastic Crate Injection Molding Machine,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine, At present, corporation name has much more than 4000 kinds of products and gained very good status and big shares on current market domestic and abroad.

GF530ceh Servo System Injection Molding Machine for Plastic Crate, We're sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

Hot Products

Hydraulic Plastic Injection Molding Machine

The ZOWEITE® hydraulic plastic injection molding machine made in China is a kind of injection molding machine with hydraulic system. It is a processing equipment that heats and melts a granular plastic into a mold cavity at high pressure and quickly, and then maintains the pressure and cools to solidify and shape it into a plastic product. , Called hydraulic injection molding machine.Injection Moulding Machine For Bottle Caps

ZOWEITE® injection moulding machine for bottle caps is used to produce all kinds of bottle caps of mineral water bottles and beverage bottles. Different molds and machines are determined according to different bottle cap sizes. Plastic bottle caps are also divided into different production processes. Only the injection molding production process needs the injection molding machine to produce.PET Preform Injection Molding Machines

ZOWEITE® PET Preform Injection Molding Machines is a special designed machine for the properties of PET material. ZOWEITE® is a high- teach enterprise specializing in R&D, production and sales of injection molding machine.Plastic Bucket Injection Molding Machines

ZOWEITE® is manufacturer and supplier for providing customers with bucket injection turnkey engineering. If you are planning to invest in new projects of Plastic Bucket Injection Molding Machines and injection mold. Then please contact us.Knife Fork And Spoon Injection Molding Machine

A Knife Fork And Spoon Injection Molding Machine is a type of manufacturing equipment used to produce plastic cutlery items such as knives, forks, and spoons through the process of injection molding.Standard Bucket Dedicated Injection Molding Machine

Standard Bucket Dedicated Injection Molding Machine is a specific type of injection molding machine designed for manufacturing standard barrels or barrels. ZOWEITE® is a professional supplier of such machines. Welcome to inquire and provide professional services according to your specific requirements.