Lens linjection molding machine Manufacturers

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Lens linjection molding machine,Low failure rate Lens lamp injection molding machine,Efficient and durable Lens lamp injection molding machine,Easy maintenance Lens lamp injection molding machine,Auto parts Lens lamp injection molding machine, We are going to do our greatest to satisfy or exceed customers' prerequisites with excellent goods, advanced concept, and economical and timely company. We welcome all clients.

Lens linjection molding machine, Many items fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't ought to waste time shopping around.

Hot Products

Plastic Container Moulding Machine

ZOWEITE® Plastic container moulding machine molded containers that is made in China factory can be straight sided or tapered, narrow or wide mouth shapes such as boxes, jars, tubs and vials. Material is injected into a cavity where pressure forces the resin to conform to the mold body. Containers are capable of holding to a tighter dimensional tolerance, and are more uniform in wall distribution. A wide variety of resins can be processed via the Plastic container moulding machine process, the most popular being polypropylene, styrene and polyethylene.Vegetable And Fruit Injection Molding Machine

ZOWEITE® Vegetable And Fruit Injection Molding Machine made in China is a special machine for producing fruit and vegetable baskets. It is a special model for disposable plastic fruit basket production equipment developed by our company according to the characteristics of fruit and vegetable baskets. The vegetable and fruit basket injection molding machine has the latest domestic technology, novel structure, high speed, high efficiency, low dryness and energy saving.Plastic Vegetable Basket Injection Molding Machine

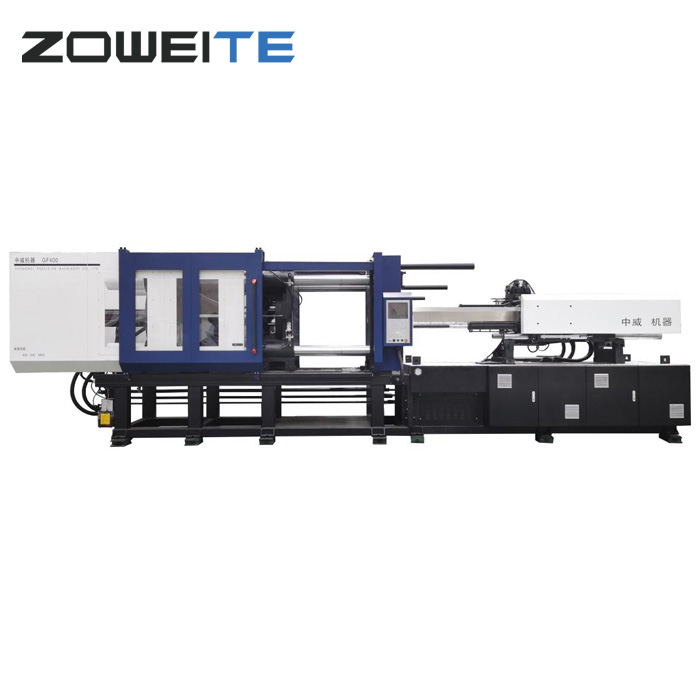

Plastic vegetable basket injection molding machine is an special designed injection molding machine for plastic vegetable basket. It is suitable for the injection molding machine of fruit basket, vegetable basket and other disposable waste turnover baskets. ZOWEITE® GF400K, GF530K and other injection molding machine are specially developed by ZOWEITE® for fruit and vegetable basket.Car Bumper Injection Molding Machine

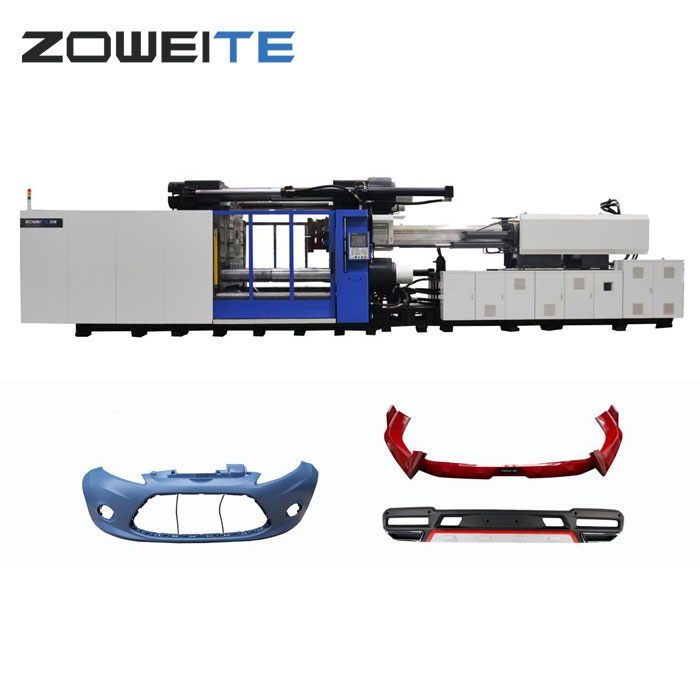

With the rapid development of automobile industry, plastic parts are more and more widely used in automobiles. The application of automobile plastic parts has significant effects on reducing automobile quality, saving fuel, promoting environmental protection and recyclability. Car Bumper Injection Molding Machine bumper mainly adopts injection molding. ZOWEITE® GF2300LB machine is specially designed for bumper.Paint Bucket Injection Molding Machine

Paint bucket injection molding machines are widely used in the manufacturing industry for producing paint containers and offer advantages like high production rates, precision, and the ability to produce large quantities of uniform and consistent paint buckets.Two Platen Packaging Injection Molding Machine

A Two Platen Packaging Injection Molding Machine is a type of injection molding machine used in the production of plastic packaging materials. Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity, which then cools and solidifies to form the desired product.