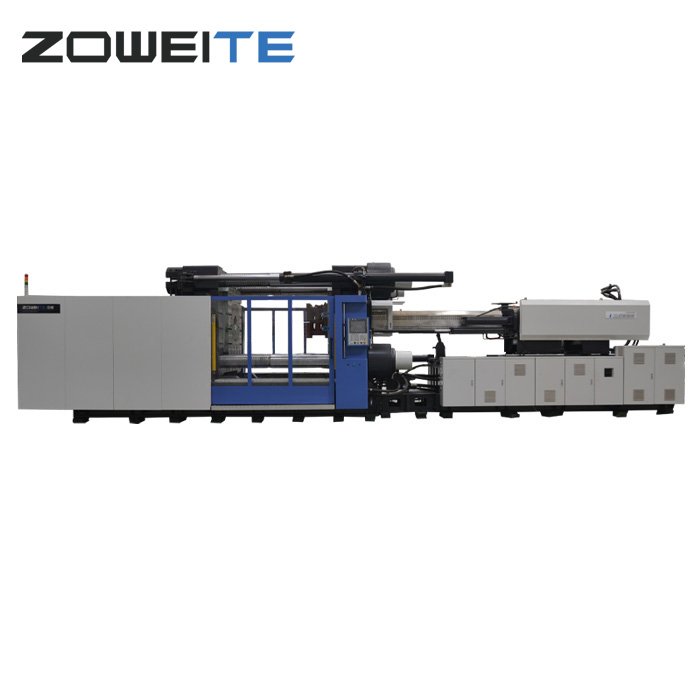

Pet Series 420 Ton Injection Molding Machine Manufacturers

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Pet Series 420 Ton Injection Molding Machine,Injection Molding Machine Servo Series Hxm730I,Injection Molding Machine Servo Series Hxm630I,Injection Molding Machine Servo Series Hxm218,Fully-Electric Hhd Series Injection Molding Machine, The concept of our corporation is "Sincerity, Speed, Services, and Satisfaction". We're going to follow this concept and get more and additional customers' fulfillment.

Pet Series 420 Ton Injection Molding Machine, With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Hot Products

2300ton Injection Molding Machine

The ZOWEITE® 2300ton injection molding machine is a relatively large injection molding machine in the injection molding machine industry. It can be specifically used to produce 120L and 240L trash cans,pallets,car bumpers,large chairs and other plastic products,the manufacturer will limit the size of the customer’s mold through a reasonable arrangement of code mold holes.Plastic Cup Molding Machine

Due to the outbreak of the new crown epidemic, the utilization rate of disposable plastic cups has gradually increased. In response to market demand, ZOWEITE has launched a high-speed injection molding machine-plastic cup molding machine. The plastic cup molding machine has advanced energy-saving technology design, and the energy-saving effect is leading the injection molding industry.Plastic bottle cap injection molding machine

ZOWEITE® Plastic bottle cap injection molding machine can produce mineral water bottle caps, automatic flip bottle caps, 5 gallon bottle caps, children’s anti-theft capsule caps, etc. ZOWEITE® machinery manufacture according to different sizes of bottle caps and customer requirements, we have developed 120 tons to 320 tons machine. We will provide the suitable machine , best price and completer bottle cap injection molding production line for customers according to their requirements.Injection Molding Machines

ZOWEITE® started our R&D of high speed injection molding machines since 2015. We had become one of the top brands in Chineses market in this specific industry of high speed injection molding machines.Basket Injection Molding Machines

The Basket Injection Molding Machines is a special model of disposable plastic fruit basket production equipment developed by our company according to the characteristics of the fruit and vegetable basket.ZOWEITE® GF400K, GF530K and other injection molding machine are specially developed by ZOWEITE® for fruit and vegetable basket.Fast food container injection machine

A fast food container injection machine, also known as a plastic injection molding machine, is a piece of equipment used in the manufacturing process of plastic fast food containers.