Plastic Transportation Crate Injection Mould Molding Manufacturers

As for aggressive selling prices, we believe that you will be searching far and wide for anything that can beat us. We are able to state with absolute certainty that for such good quality at such costs we've been the lowest around for Plastic Transportation Crate Injection Mould Molding,High Quality Injection Molding Machine for Plastic Crate,Servo Injection Molding Machine for Plastic Basket Bucket Crate,Hot Sell Plastic Crate Injection Molding Machine,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine, You would not have any communication problem with us. We sincerely welcome prospects all around the globe to call us for business enterprise cooperation.

Plastic Transportation Crate Injection Mould Molding, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We're looking for the wholesale, Drop ship. Make sure you contact us if you are interesting our solutions. Hope to do business with you all. High quality and fast shipment!

Hot Products

High Pressure Moulding Machine

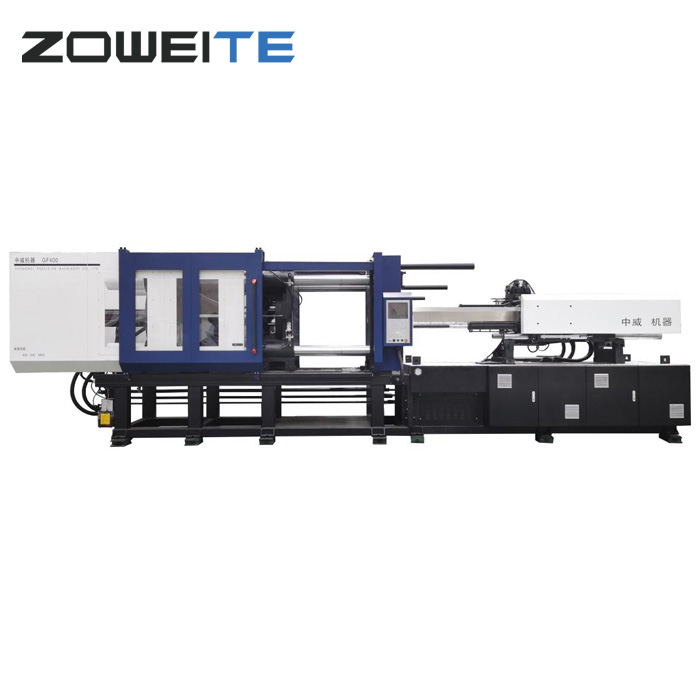

The injection pressure is the force exerted by the reciprocating screw to push the molten plastic resin into the mold cavity, which is about 90% of the capacity. It is balanced with the clamping pressure of the machine and calculated according to size and shape of the parts and the size of gate opening. Compared with ordinary injection molding machine , the ZOWEITE® high pressure moulding machine made in China of has secondary mold locking and pressure maintaining.Milk Tea Cup Injection Molding Machine

ZOWEITE® Milk tea cup injection molding machine from China is also a kind of thin-wall packaging injection molding, which also has high requirements for injection pressure and machine. ZOWEITE® KC series injection molding machine which is a special machine for produce milk tea cup.Plastic Crate Injection Molding Machine

Plastic crates are manufactured through a process called plastic injection molding. An ZOWEITE® plastic crate injection molding machine mold made in China is a machine that takes raw plastic product, or stock, and processes it into a usable product. plastic crate injection molding machine molders begin with a collection of stock in a hopper which is directed into a conveyance channel. A screw will turn in the conveyance channel which combined with heating, helps to liquefy the plastic in preparation for the mold.2300ton Injection Molding Machine

The ZOWEITE® 2300ton injection molding machine is a relatively large injection molding machine in the injection molding machine industry. It can be specifically used to produce 120L and 240L trash cans,pallets,car bumpers,large chairs and other plastic products,the manufacturer will limit the size of the customer’s mold through a reasonable arrangement of code mold holes.PVC tube injection molding machine

ZOWEITE® PVC tube injection molding machine is standard machine and it is suitable for produce various tubes. As a professional manufacturer and supplier of PVC tube injection molding machines, ZOWEITE PVC tube injection molding machine has always provided high-quality injection molding equipment for manufacturers in the building materials industry at home and abroad to help customers develop, Highly praised by customers.PET preform for water bottle injection molding machine

PET preforms come in various sizes and neck finishes to adapt to different bottle designs and applications. ZOWEITE® can customize PET preform for water bottle injection molding machine according to customer requirements.