Auto parts bumper injection molding machine Manufacturers

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Auto parts bumper injection molding machine,Auto bumper injection machine,1500 tons Auto bumper injection molding machine,2300 tons Auto bumper injection molding machine,Easy maintenance Auto bumper injection molding machine, We goal at Ongoing system innovation, management innovation, elite innovation and sector innovation, give full play for the overall advantages, and constantly make improvements to support excellent.

Auto parts bumper injection molding machine, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we're doing for. We have been an absolutely reliable partner for you personally in China. Of course, other services, like consulting, can be offered too.

Hot Products

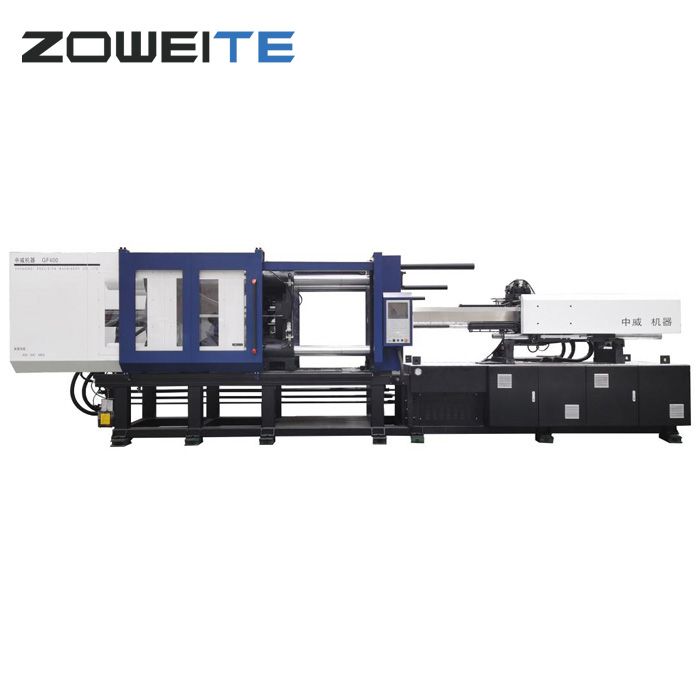

400 Ton Injection Molding Machine

The ZOWEITE® 400 ton injection molding machine has a clamping force of 4000KN, and the 400 ton large screw machine is about 1000 grams, and the maximum can reach 700~800 grams. The products are different, and the results are different.IML Plastic bucket Injection Molding Machine

In coating construction, coating bucket is indispensable. A good paint bucket requires not only environmental protection and health of plastics, small water absorption, but also strong compression and impact resistance, as well as good heat and chemical resistance. Of course, high-quality paint bucket with these advantages must be inseparable from high-quality paint barrel production equipment and ZOWEITE® IML plastic bucket injection molding machine.Disposable Tableware Injection Moulding Machine

ZOWEITE® factory is disposable tableware injection moulding machine manufacturer and supplier. Plastic tableware is becoming more and more popular in our daily life.Plastic Bucket Injection Molding Machines

ZOWEITE® is manufacturer and supplier for providing customers with bucket injection turnkey engineering. If you are planning to invest in new projects of Plastic Bucket Injection Molding Machines and injection mold. Then please contact us.High Speed Injection Molding Machines

ZOWEITE® started our R&D of High Speed Injection Molding Machines since 2015. We had become one of the top brands in Chineses market in this specific industry of high speed injection molding machines.Two Platen Packaging Injection Molding Machine

A Two Platen Packaging Injection Molding Machine is a type of injection molding machine used in the production of plastic packaging materials. Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity, which then cools and solidifies to form the desired product.