Electric Servo Injection Molding Machine Manufacturers

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Electric Servo Injection Molding Machine,Injection molding machine,Production Injection Molding Machine,Basket Injection Molding Machine,Bucket Injection Molding Machine, Our aim is "blazing new ground, Passing Value", in the future, we sincerely invite you to grow up with us and make a bright future together!

Electric Servo Injection Molding Machine, We've got been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We now have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We've been sincerely looking forward to establishing business relationships with friends from at home and abroad.

Hot Products

Fully Automatic 780 Tons Injection Molding Machine

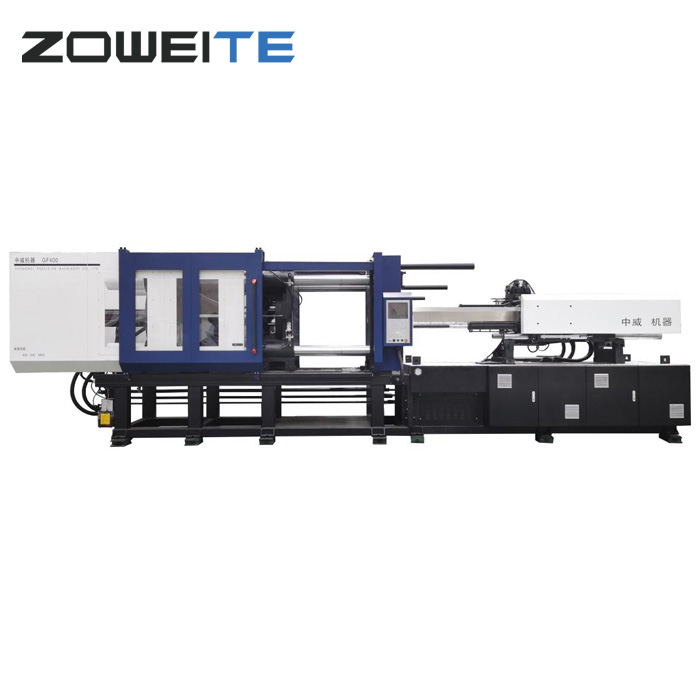

The ZOWEITE® Fully Automatic 780 Tons Injection Molding Machine made in China is the molding equipment that makes thermoplastic or thermosetting plastics into various kinds of plastic products with plastic molding molds. The injection molding machine heats the plastic and applies high pressure to the molten plastic to make it shoot out and fill the mold cavity.400 Ton Molding Machine

ZOWEITE® has 30 years of experience in this industry and obtained ISO 9001 and SGS certification. ZOWEITE® has many high-quality machines, i will focus on the 400 ton molding machine.If you are interested in our products, then please contact us, we will give you the most suitable quotation.PVC tube injection molding machine

ZOWEITE® PVC tube injection molding machine is standard machine and it is suitable for produce various tubes. As a professional manufacturer and supplier of PVC tube injection molding machines, ZOWEITE PVC tube injection molding machine has always provided high-quality injection molding equipment for manufacturers in the building materials industry at home and abroad to help customers develop, Highly praised by customers.Fruit crate injection molding machine

The ZOWEITE® Fruit crate injection molding machine has standard models and special models. The fruit crate special machine is suitable for producing disposable black fruit baskets and processing various vegetable crates. Fruit crate injection molding machine adopts special plasticizing system, which is more efficient and durable. Its multiple actions are executed synchronously to shorten the forming cycle. It has fast injection and forming efficiency, which is more suitable for the production of fruit and vegetable crate injection molding machine. ZOWEITE® manufacturers will provide customers with the suitable, high quality machines and the best prices according to their needs.Fruit and Vegetable Baskets Injection Molding Machine

We come from ZOWEITE® Injection Molding Machine Factory to provide customers with the most efficient and stable machinery and equipment.Two Platen Packaging Injection Molding Machine

A Two Platen Packaging Injection Molding Machine is a type of injection molding machine used in the production of plastic packaging materials. Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity, which then cools and solidifies to form the desired product.