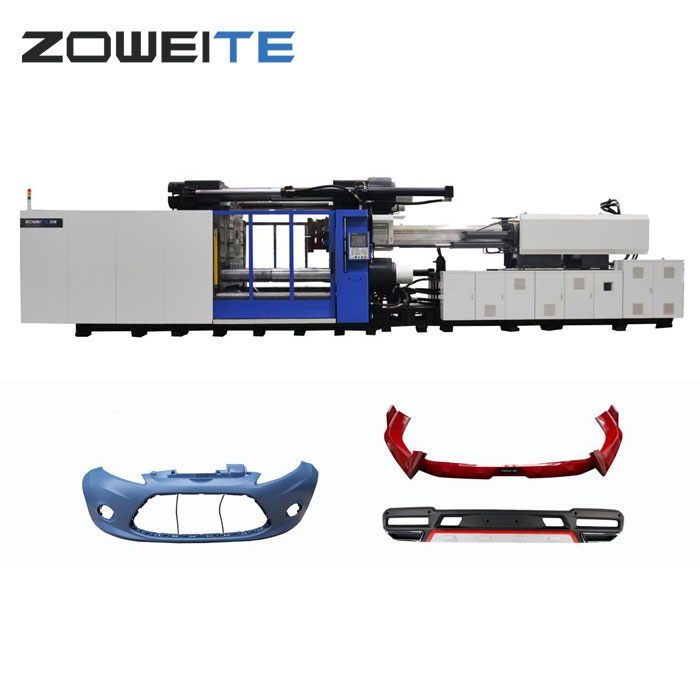

New Auto bumper injection molding machine Manufacturers

We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for New Auto bumper injection molding machine,Auto bumper injection machine,1500 tons Auto bumper injection molding machine,2300 tons Auto bumper injection molding machine,Easy maintenance Auto bumper injection molding machine, With superb service and quality, and an enterprise of foreign trade featuring validity and competitiveness, that will be trusted and welcomed by its clients and creates happiness to its employees.

New Auto bumper injection molding machine, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !You should your inquiry for more details or request for dealership in selected regions.

Hot Products

Servo Molding Machine

The servo molding machine from China is an injection molding machine with a servo system. It uses a servo motor. It is a more precise control machine. ZOWEITE® servo molding machinehas 30 years of industry experience accumulation. These machines have passed ISO9001 certification and have quality assurance.Pet Preform Injection Molding Machine

The chemical name of PET is polyethylene terephthalate, also known as polyester. At present, GF-PET is the most used by customers, mainly for preforms, so the sales of ZOWEITE® PET preform injection molding machines from China have soared. The rheology of PET in the molten state is better, and the pressure has a greater influence on the viscosity than the temperature. Therefore, the pressure is mainly used to change the fluidity of the melt.Car Bumper Injection Molding Machine

With the rapid development of automobile industry, plastic parts are more and more widely used in automobiles. The application of automobile plastic parts has significant effects on reducing automobile quality, saving fuel, promoting environmental protection and recyclability. Car Bumper Injection Molding Machine bumper mainly adopts injection molding. ZOWEITE® GF2300LB machine is specially designed for bumper.Garbage Can Injection Molding Machine

ZOWEITE® Garbage can injection molding machine made in China is a plastic garbage can injection molding production process, which is: raw material mixing - mixed raw material addition - commissioning process, melting to liquid through high-temperature screw - injecting into mold cavity - cooling molding - opening mold to take out products, and then complete the production of plastic garbage can.Horizontal High Speed Injection Molding Machine

The ZOWEITE® horizontal high speed injection molding machine made in China adopts accumulator assisted injection, which improves the injection speed, faster machine cycle and high production efficiency. It is especially suitable for the production of thin-walled products.Electric Servo Injection Molding Machine

ZOWEITE has 30 years experience in Electric Servo Injection Molding Machine. ZOWEITE provide turnkey project for our customers. And always improve our machines performance to help customers be more cometitive in the current market. Do not hesitate to contact us for the latest technology of IMM.

WhatsApp & WeChat : 008618633246818

Admin@milestonemachine.cn