fork injection molding machine Manufacturers

With state-of-the-art technologies and facilities, strict high-quality management, reasonable price tag, top-quality service and close co-operation with clients, we're devoted to delivering the top value for our consumers for fork injection molding machine,Knife,fork and spoon injection molding machine,Knife injection molding machine,spoon injection molding machine,injection molding machine, To find out more about what we could do for you personally, call us anytime. We look forward to setting up good and long-term company interactions along with you.

fork injection molding machine, With good quality, reasonable price and sincere service, we enjoy a good reputation. Items are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

Hot Products

Automatic Injection Moulding Machine

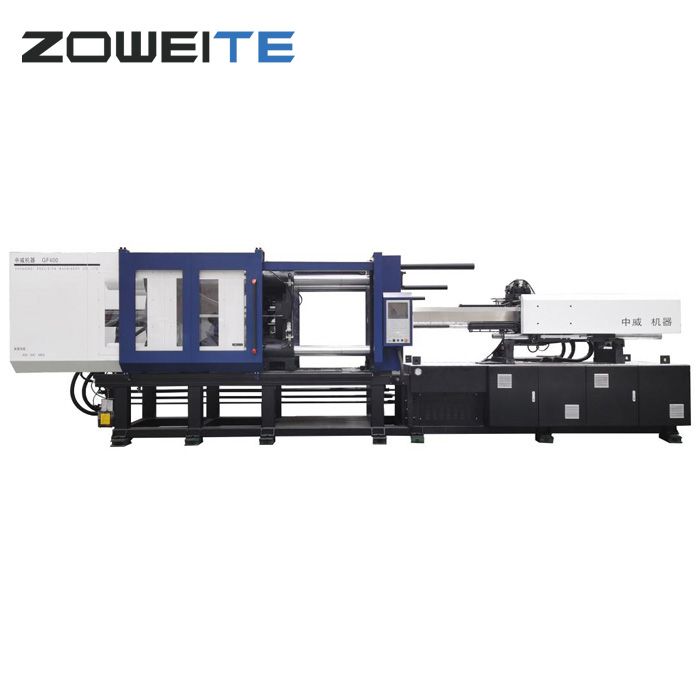

A compact, precision, ZOWEITE® automatic injection moulding machine with China manufacturers has a twin-cylinder hydraulic 10-ton clamp with a vertical injection unit, permitting the use of molds that apply a parting line injection design.Plastic Vegetable Basket Injection Molding Machine

Plastic vegetable basket injection molding machine is an special designed injection molding machine for plastic vegetable basket. It is suitable for the injection molding machine of fruit basket, vegetable basket and other disposable waste turnover baskets. ZOWEITE® GF400K, GF530K and other injection molding machine are specially developed by ZOWEITE® for fruit and vegetable basket.High Speed Plastic Making Machine

ZOWEITE® High speed plastic making machine can also be calling high speed injection molding machine or high speed injection machine. Tianjin Yihe Zhongwei (ZOWEITE) Precision Machinery Co., Ltd is a high-tech enterprise specialized in designing, manufacturing and selling various types of high-precision, energy saving, stable performance injection molding machines in China.Plastic Cup Molding Machine

Due to the outbreak of the new crown epidemic, the utilization rate of disposable plastic cups has gradually increased. In response to market demand, ZOWEITE has launched a high-speed injection molding machine-plastic cup molding machine. The plastic cup molding machine has advanced energy-saving technology design, and the energy-saving effect is leading the injection molding industry.320 tons injection molding machine

ZOWEITE® 320 tons injection molding machine is a standard machine. It can produce this kind of different plastic products, such as plastic fittings, PET preform, nylon ties, lampshades and other plastic products. In addition to standard machines, we also have high speed machines and special machines. ZOWEITE manufactures will recommend the suitable and high quality machines according customer’s needs, and provide professional injection molding solutions according to customer’s needs, and provide professional injection molding solutions according to customer’s specific needs, so as to help customers gain advantages in market competition.Logistic Crate Injection Molding Machine

ZOWEITE® has rich experience for producing injection molding machines more than 30 years, we keep on innovating and updating our technology.Today I would like to share our Logistic crate injection molding machine and mold information with you.