Hot Sell Plastic Crate Injection Molding Machine Manufacturers

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Hot Sell Plastic Crate Injection Molding Machine,High Quality Injection Molding Machine for Plastic Crate,Servo Injection Molding Machine for Plastic Basket Bucket Crate,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine,Plastic Transportation Crate Injection Mould Molding, Welcome your enquiry, most effective service will likely be provided with full heart.

Hot Sell Plastic Crate Injection Molding Machine, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a ought to in your case personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We're confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

Hot Products

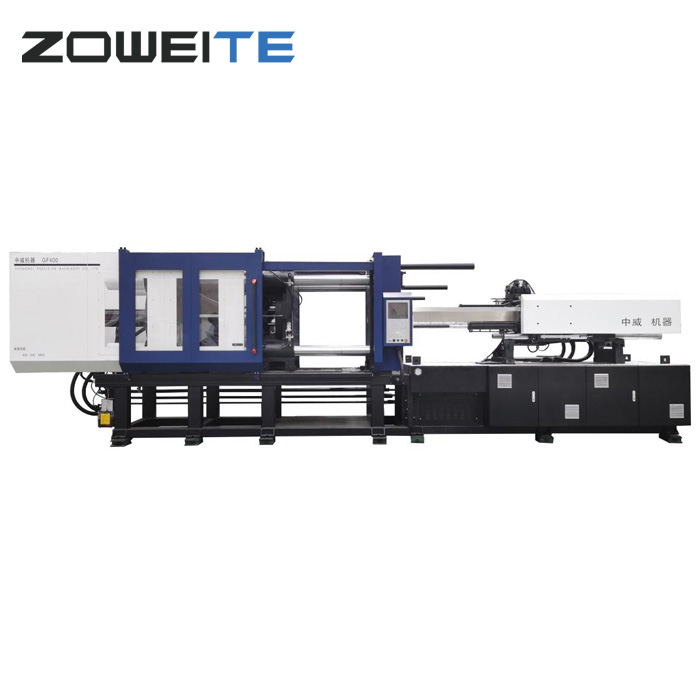

Horizontal Injection Moulding Machine

ZOWEITE® Horizontal Injection Moulding Machine made in China is also known as molding machine or injection machine. It is the main molding equipment that uses plastic molding molds to make thermoplastic or thermosetting plastics into plastic products of various shapes. The injection molding machine can heat the plastic and apply high pressure to the molten plastic to make it shoot our and fill the mold cavity.Pet Preform Machine

ZOWEITE® PET preform machine made in China series is specially designed and manufactured according to PET material molding technology, such as special design of screw and cylinder, precision controller for cylinder heating, pull rod space, nozzle, injection system,amplification motor and oil pump. Our PET preform machine is widely used in different PET molding products, including PET water preforms, soft drink bottle preforms, edible oil bottle preforms, 3 gallon and 5 gallon PET preform, etc.Pet Preform Injection Molding Machine

The chemical name of PET is polyethylene terephthalate, also known as polyester. At present, GF-PET is the most used by customers, mainly for preforms, so the sales of ZOWEITE® PET preform injection molding machines from China have soared. The rheology of PET in the molten state is better, and the pressure has a greater influence on the viscosity than the temperature. Therefore, the pressure is mainly used to change the fluidity of the melt.Plastic Trash Can Special Injection Molding Machine

Trash can manufacturers have designed sorted trash cans for use in different places such as households, streets, medical treatments, companies, etc. Such large-scale and different types of barrel production requirements will inevitably require injection molding machines that produce trash cans to support. ZOWEITE® Injection Molding Machine has launched a special injection molding machine for plastic trash cans. The special injection molding machine for plastic trash cans has two models, GF1500 and GF2300, which can produce 120L and 240L trash cans. Plastic Trash Can Special Injection Molding Machine can be selected according to different capacity trash cans.Two Platen Moulding Injection Machine

Horizontal injection molding machines include two platen injection moulding machine and three plate injection molding machine. The two platen injection moulding machine directly uses high pressure oil cylinder to realize high pressure mold locking, and the mold locking force can be set at will according to the actual needs. Welcome to buy ZOWEITE® Two platen moulding injection machine from us.Disposable Plastic box moulding machine

High-speed injection molding machine-disposable box moulding machine has a stable high pressure and high injection system, which is suitable for molding thinner products. Therefore, ordinary injection molding machines cannot produce the disposable lunch boxes required by the market. The warranty period of the machine is one year, if you are interested in our products, please contact us and we will definitely give you a best price. Welcome to buy ZOWEITE® Disposable Plastic box moulding machine from us China factory.