Injection Machine Plastic Spoons Manufacturers

It adheres to the tenet ""Honest, industrious, enterprising, innovative"" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Injection Machine Plastic Spoons,Plastic spoons injection machine,Plastic Spoons Injection Machine,Vertical Injection Machine,Plastic Injection Molding Machine, Welcome your enquiry, most effective service will likely be provided with full heart.

Injection Machine Plastic Spoons, We only supply quality goods and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products and solutions etc that can according to customer's requirement.

Hot Products

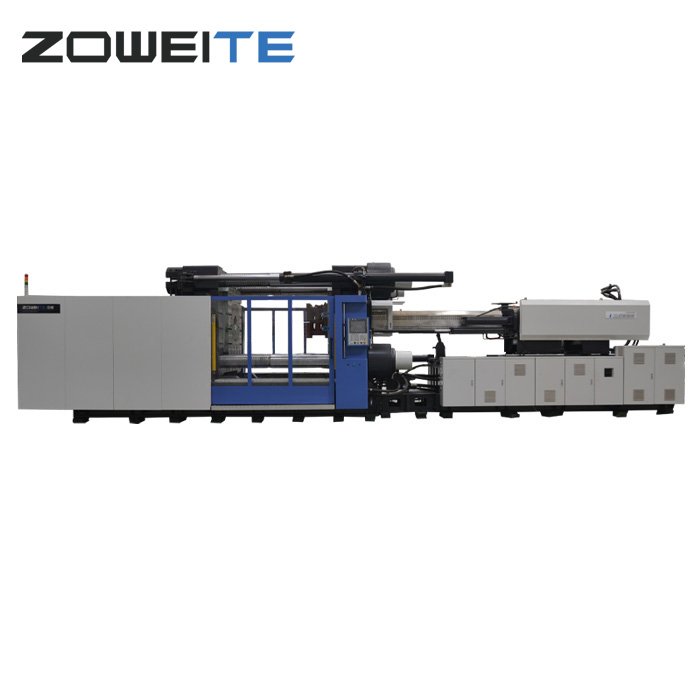

Medical Sharp Bucket Injection Molding Machine

ZOWEITE® Medical Sharp Bucket Injection Molding Machine made in China is a machine specially used to produce medical sharps barrels. It has the advantages of high technology, high configuration and high output.Plastic Crate Injection Molding Machine

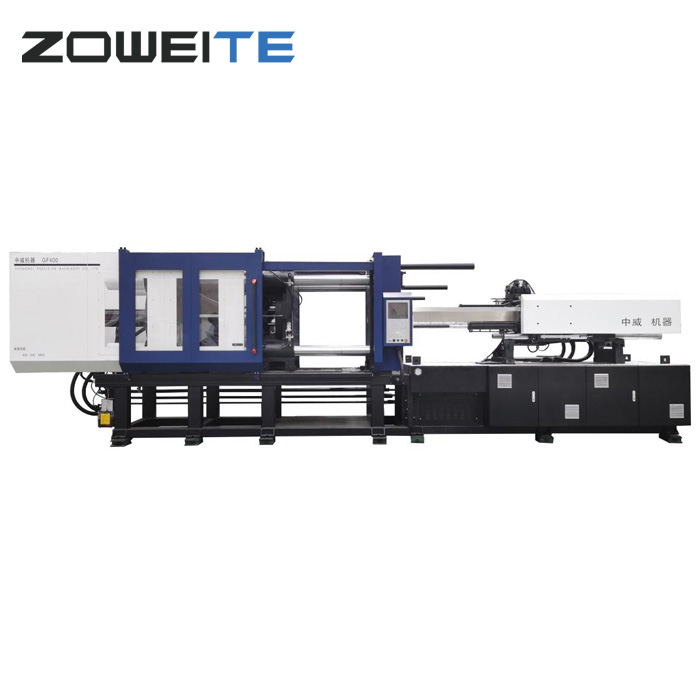

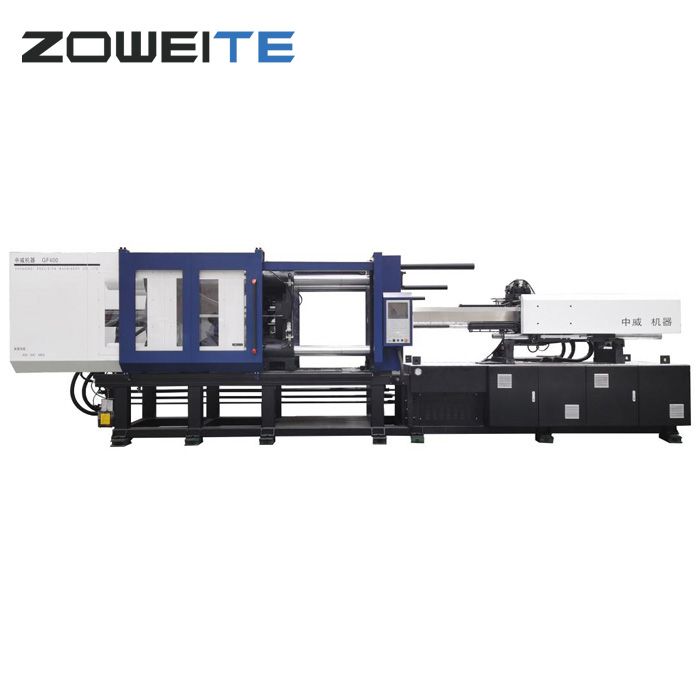

Plastic crates are manufactured through a process called plastic injection molding. An ZOWEITE® plastic crate injection molding machine mold made in China is a machine that takes raw plastic product, or stock, and processes it into a usable product. plastic crate injection molding machine molders begin with a collection of stock in a hopper which is directed into a conveyance channel. A screw will turn in the conveyance channel which combined with heating, helps to liquefy the plastic in preparation for the mold.Vegetable and Fruit Basket Making Machine

ZOWEITE® vegetable and fruit basket making machine has a short cycle cycle, high production efficiency, abrasion-resistant screw barrel and screw, and has a very high cost performance. It is a special model specially developed for turnover baskets, plastic baskets, fruit baskets, and seafood basket storage boxes.Plastic Oil Drum Injection Molding Machine

ZOWEITE® Plastic oil drum injection molding machine in China can be used to produce a series of plastic buckets. Such as machine oil buckets and paint buckets. The faults of the machine plastic oil drum injection molding machine are diverse and can be classified from different angles.Plastic bottle cap injection molding machine

ZOWEITE® Plastic bottle cap injection molding machine can produce mineral water bottle caps, automatic flip bottle caps, 5 gallon bottle caps, children’s anti-theft capsule caps, etc. ZOWEITE® machinery manufacture according to different sizes of bottle caps and customer requirements, we have developed 120 tons to 320 tons machine. We will provide the suitable machine , best price and completer bottle cap injection molding production line for customers according to their requirements.Lens lamp injection molding machine

The ZOWEITE® lens lamp injection molding machine is an injection molding machine specially used to produce optical lens lamps. The lens lamp injection molding machine is a new injection molding machine developed by ZOWEITE. This injection molding machine has a low failure rate, adopts a dedicated system, is efficient and durable, and is easy to maintain. We can provide you with turnkey projects including factory design, entire production line and tooling, machine installation and worker training. We will definitely offer you the best price.