Plastic Chair and Crate Injection Molding Machine Manufacturers

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of Plastic Chair and Crate Injection Molding Machine,High Quality Injection Molding Machine for Plastic Crate,Servo Injection Molding Machine for Plastic Basket Bucket Crate,Hot Sell Plastic Crate Injection Molding Machine,Customized Plastic Bucket Crate Basin Container Making Injection Molding Machine, For further info, you should usually do not hesitate to call us. All inquiries from you might be extremely appreciated.

Plastic Chair and Crate Injection Molding Machine, we've been sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

Hot Products

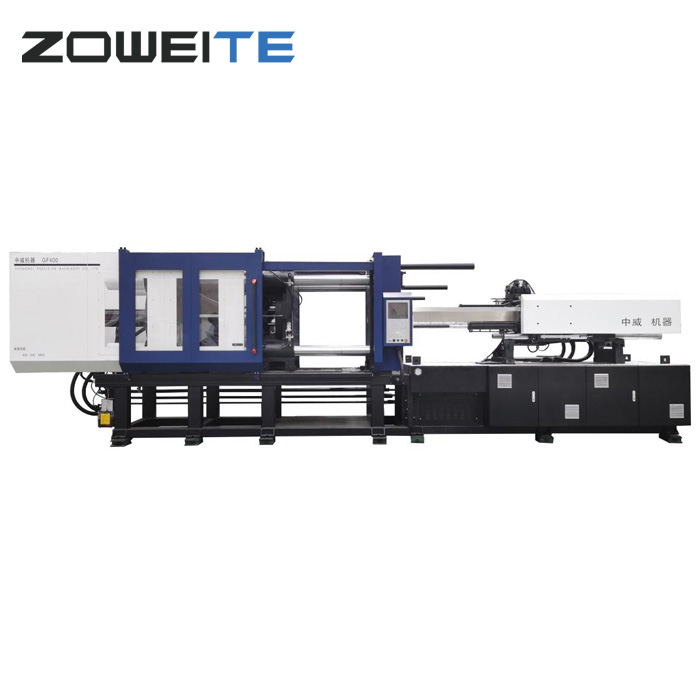

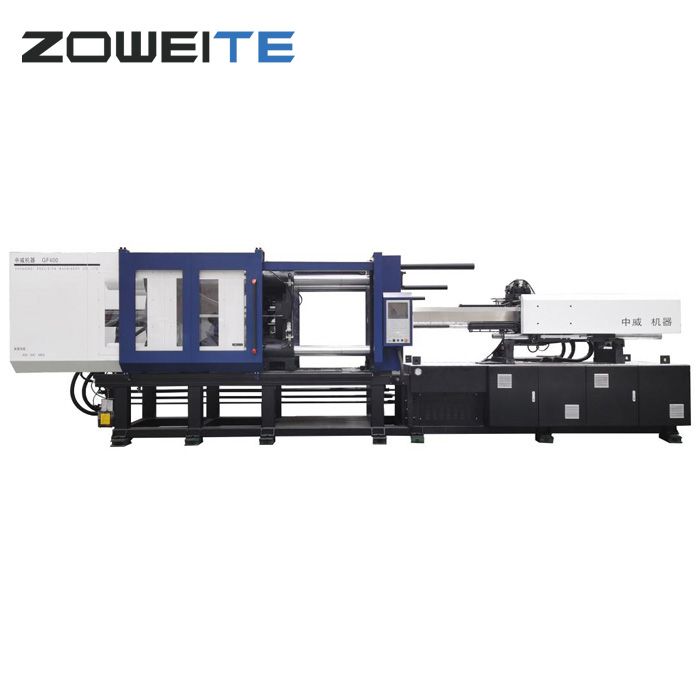

Hydraulic Plastic Injection Molding Machine

The ZOWEITE® hydraulic plastic injection molding machine made in China is a kind of injection molding machine with hydraulic system. It is a processing equipment that heats and melts a granular plastic into a mold cavity at high pressure and quickly, and then maintains the pressure and cools to solidify and shape it into a plastic product. , Called hydraulic injection molding machine.Pet Bottle Preform Machine

ZOWEITE® PET Bottle Preform Machine made in China is an optimized injection molding machine for PET injection molding. It is the important PET equipment in the manufacturing process of PET bottle blank. Even in the whole PET Bottle Preform Machine are specially designed according to the characteristics of PET materials.Plastic Vegetable Basket Injection Molding Machine

Plastic vegetable basket injection molding machine is an special designed injection molding machine for plastic vegetable basket. It is suitable for the injection molding machine of fruit basket, vegetable basket and other disposable waste turnover baskets. ZOWEITE® GF400K, GF530K and other injection molding machine are specially developed by ZOWEITE® for fruit and vegetable basket.Tray Injection Molding Machine

The Tray injection molding machine is one of the two platen machines. The Tray injection molding machine is specially used to produce plastic pallets used in the industry. ZOWEITE® provide Turn-key project for our customers, including plant design, whole injection molding machines production lines sourcing, machines installation, testing and commissioning.PET Bottle Preform Moulding Machine

ZOWEITE® Machinery company has developed a special PET bottle preform moulding machine according customers requirements.ZOWEITE GF260/GF320/GF400 injection molding machine is a special designed machine for PET preform.ZOWEITE Machinery manufacturer are in a good position not only to supply you high quality machinery, but also the excellent after sales service. Well-trained engineers will offer you any technical support.Fruit crate injection molding machine

The ZOWEITE® Fruit crate injection molding machine has standard models and special models. The fruit crate special machine is suitable for producing disposable black fruit baskets and processing various vegetable crates. Fruit crate injection molding machine adopts special plasticizing system, which is more efficient and durable. Its multiple actions are executed synchronously to shorten the forming cycle. It has fast injection and forming efficiency, which is more suitable for the production of fruit and vegetable crate injection molding machine. ZOWEITE® manufacturers will provide customers with the suitable, high quality machines and the best prices according to their needs.