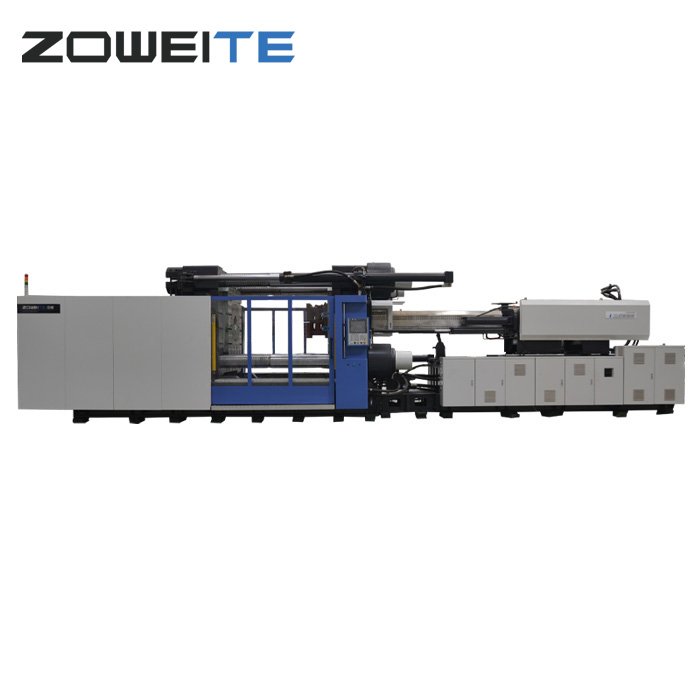

thin wall packaging injection molding machine Manufacturers

We believe in: Innovation is our soul and spirit. Excellent is our life. Buyer want is our God for thin wall packaging injection molding machine,PET thin wall packaging high speed injection molding machine,thin wall packaging high speed injection molding machine,high speed injection molding machine,PET injection molding machine, High-quality is factory's everyday living , Focus on customers' demand would be the source of organization survival and advancement, We adhere to honesty and good faith doing the job attitude, seeking forward towards your coming !

thin wall packaging injection molding machine, We are proud to supply our items to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Hot Products

Cap Molding Machine

ZOWEITE® Cap molding machine in China is a machine used to produce plastic bottle caps. What is the essential performance of a high-quality bottle cap? It is undoubtedly hermeticity and safety. Need to consider easy opening, weather resistance and impact resistance. Nowadays, consumers' requirements for packaging are constantly increasing, and the Chinese market has higher and higher requirements for the accuracy, efficiency, stability and flexibility of the equipment for producing cap molding machines.New Injection Molding Machine

ZOWEITE® injection molding machine only sells new injection molding machine, not old ones. We are a professional injection molding machine manufacturer. We have been in this industry for 30 years and have rich experience.Pet Preform Injection Molding Machine

The chemical name of PET is polyethylene terephthalate, also known as polyester. At present, GF-PET is the most used by customers, mainly for preforms, so the sales of ZOWEITE® PET preform injection molding machines from China have soared. The rheology of PET in the molten state is better, and the pressure has a greater influence on the viscosity than the temperature. Therefore, the pressure is mainly used to change the fluidity of the melt.1500 Ton Injection Molding Machine

The ZOWEITE® 1500 ton injection molding machine made in China is a large-scale machine in the injection molding machine industry. The 1500 ton injection molding machine is also a special injection molding machine for environmental protection, medical, and household trash cans. It can be used to produce a 120L trash can.Tray Injection Molding Machine

The Tray injection molding machine is one of the two platen machines. The Tray injection molding machine is specially used to produce plastic pallets used in the industry. ZOWEITE® provide Turn-key project for our customers, including plant design, whole injection molding machines production lines sourcing, machines installation, testing and commissioning.Thin wall products injection molding machine

A thin wall products injection molding machine is a specialized type of injection molding machine designed to produce thin-walled plastic products with high precision and efficiency.ZOWEITE® has 30 years experience in injection molding machine industry.