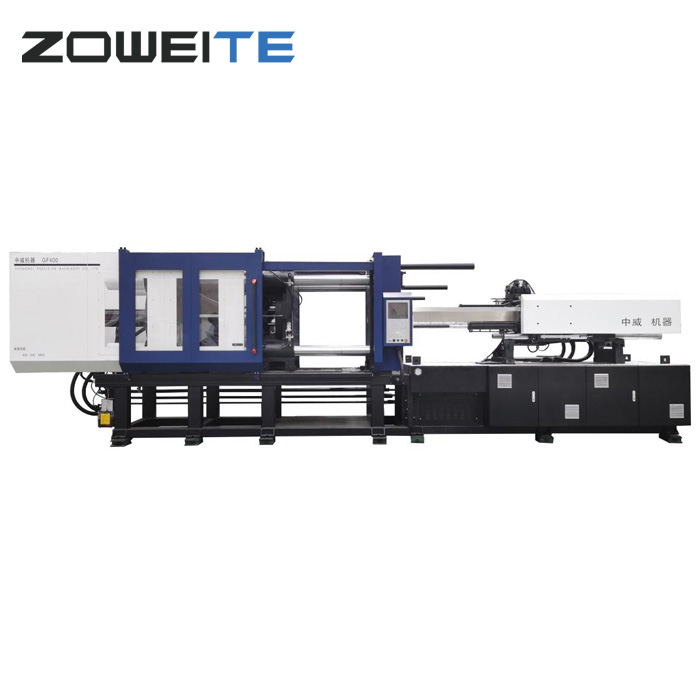

Easy maintenance320 tons injection molding machine Manufacturers

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Easy maintenance320 tons injection molding machine,High-speed 320 tons injection molding machine,High Response Hybrid Servo System 320 tons injection molding machine,Rigid support structure320 tons injection molding machine,Food container320 tons injection molding machine, Leading the trend of this field is our persistent objective. Supplying 1st class products and solutions is our intention. To make a beautiful long term, we would want to cooperate with all friends at your house and abroad. Should you've any interest within our products, remember to usually do not be reluctant to get in touch with us.

Easy maintenance320 tons injection molding machine, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Hot Products

Bottle Preform Making Machine

ZOWEITE® Bottle preform making machine is a large machine specially used to produce plastic bottle preforms. In life, the use of plastic bottles is more and more widespread. Mass production of plastic bottles has become a demand. The plastic bottle is first produced by the bottle preform making machine, and then blown into the shape of the plastic preform by the blow molding machine. This shows that the production of plastic preforms is the key. Bottle preforms making machine are very important for the production of machine raw tea plastic preforms, which are related to the tightness of plastic bottles.Fully Automatic 780 Tons Injection Molding Machine

The ZOWEITE® Fully Automatic 780 Tons Injection Molding Machine made in China is the molding equipment that makes thermoplastic or thermosetting plastics into various kinds of plastic products with plastic molding molds. The injection molding machine heats the plastic and applies high pressure to the molten plastic to make it shoot out and fill the mold cavity.Plastic Trash Can Special Injection Molding Machine

Trash can manufacturers have designed sorted trash cans for use in different places such as households, streets, medical treatments, companies, etc. Such large-scale and different types of barrel production requirements will inevitably require injection molding machines that produce trash cans to support. ZOWEITE® Injection Molding Machine has launched a special injection molding machine for plastic trash cans. The special injection molding machine for plastic trash cans has two models, GF1500 and GF2300, which can produce 120L and 240L trash cans. Plastic Trash Can Special Injection Molding Machine can be selected according to different capacity trash cans.Plastic Paint Bucket Making Machine

ZOWEITE is manufacturer and supplier for providing customers with bucket injection turnkey engineering. If you are planning to invest in new projects of paint bucket injection molding machine and injection mold. Then please contact us.Welcome to buy Plastic Paint bucket making machine from us.Plastic pallet injection moulding machine

ZOWEITE® Plastic pallet injection moulding machine is a machine that produces various types of pallets, such as warehouse pallets, transportation pallets, industrial pallets, etc. Plastic pallet injection moulding machine generally uses two platen machine. ZOWIETE is a supplier and manufacturer of plastic pallet injection molding machines.Fruit Vegetable Basket Injection Molding Machine

Today I would like to share our Fruit Vegetable basket injection molding machine and mold information with you.